LED Chip Types: DIP LED vs SMD LED vs COB LED

Different types of LED chip: DIP LED, SMD LED, COB LED

Ever since the invention of the DIP LED in 1962 by Nick Holonyak that paved the way for the modern LED technology as we know it, the LED industry has been innovating it to promote better use, versatility and power efficiency.

Choosing LED chip types is like choosing the right wallet; there are different types and models that provide more or less features depending on what you might need.

Looking at DIP LED

What is DIP LED?

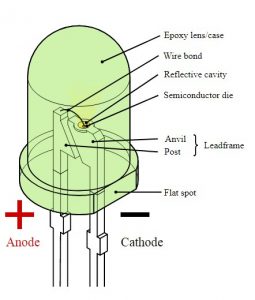

DIP stands for Dual In-Line Package. DIP LEDs are the traditional LED lights, the ones people would most likely think of when they picture an LED.

Design of DIP LED

DIP LEDs are highly recognizable by their “pill” or “bullet” shaped design (≤5mm wide), and the long contacts that extend from the bottom of the LED which can be welded on a circuit board making it more durable against impacts and blows.

DIP LEDs are heavier and wider than the newer types of LED chips.

You can find more technical details for DIP LED here.

Applications of DIP LED

Although old, DIP LEDs are still a great product thanks to their brightness and resistance. Suited for >P10 screens (P10 = pixel pitch of 10mm; the lower the pixel pitch, the higher the resolution) that will be viewed at a far distance.

You can learn more about LED screens here.

DIP LEDs can also be used as accent lighting such as rope lighting.

Looking at SMD LED

What is SMD LED?

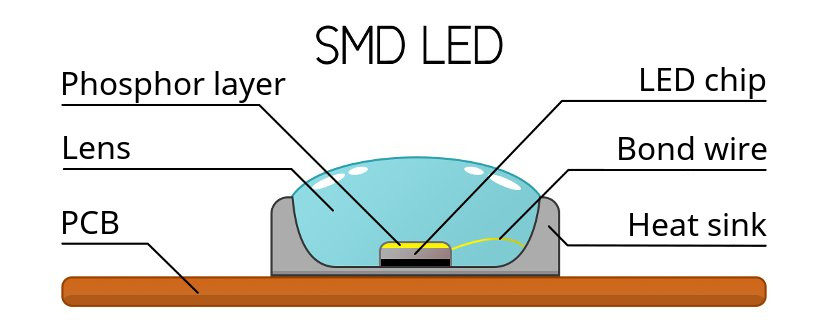

SMD stands for Surface Mounted Device, also known as SMT which stands for Surface Mounted Technology. SMD LEDs are the most popular type of LED chip and the next in line after the DIP LED, bringing in a myriad of much needed improvements.

There are numerous types of SMD LEDs, which comes in varied shapes and sizes. The most common and popular ones being SMD 3528, SMD 5050 and SMD 2835.

Design of SMD LED

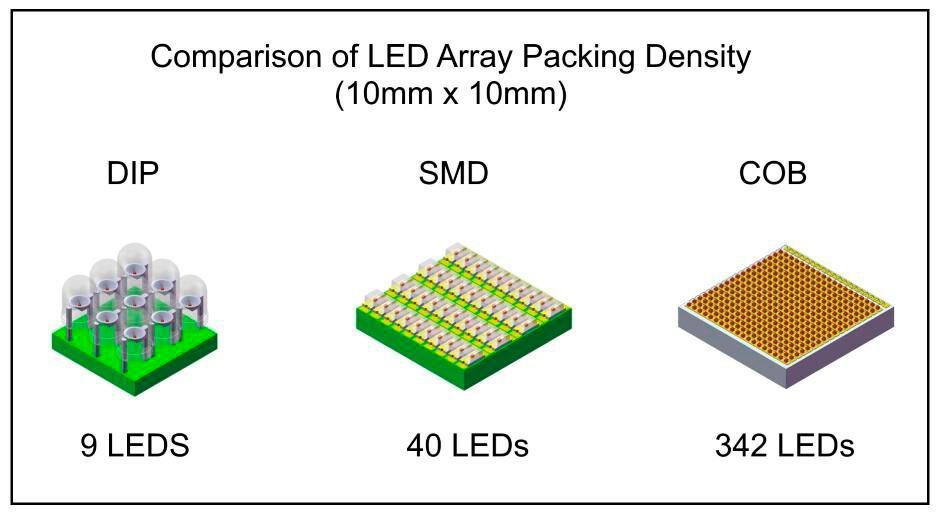

SMD LEDs introduces a smaller, lighter and flatter design than its predecessor (DIP LEDs). They are usually mounted on a circuit board which allows manufacturers to place the LEDs closer together, which results in taking considerably less space.

SMD LED consists of three colours mounted on a die to form one seamless diode.

Applications of SMD LED

SMD LEDs are widely used in home illumination, industrial lighting systems, in vehicles, advertising, backlighting and an abundant of other lighting applications.

There are also SMD LEDs with the RGB system that are used for decorative lighting.

Different types of SMD LEDs provide different lumen outputs. SMD 3528 (6-7 lumens), SMD 5050 (18-20 lumens), SMD 2835 (22-24 lumens), per SMD LED wafer.

Looking at COB LED

What is COB LED?

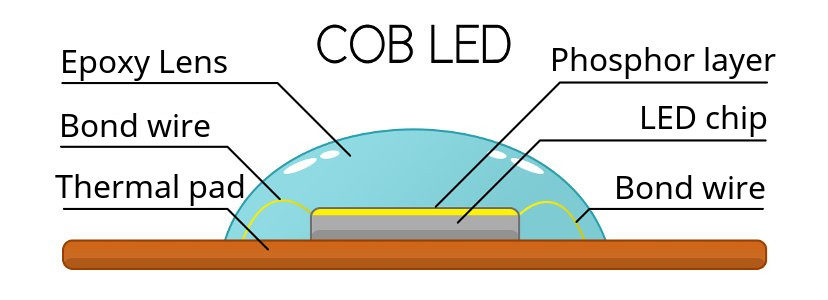

COB stands for Chip-On-Board. COB LEDs are the latest and most advanced entrants to the LED market, with more improvements to outperform its predecessors.

Design of COB LED

COB LEDs offer an even more condensed design due to it using multiple diodes, usually 9 or more and packaged together as a single lighting module.

When lit, you cannot see the individual chips, rather the appearance is that of a lighting panel; unlike SMDs and DIPs.

Applications of COB LED

The application possibilities for COB LEDs encompass a wide range. While these devices could be used for higher output general lighting, the primary use for COB LEDs would be high-bay lighting, street lights, and high-output track lights and downlights.

COB LEDs are also used in your phones and cameras.

Summary of differences between the LED chip types

Brightness and Energy Efficiency

COB LEDs are known for better lumen-to-watt ratios. COB LEDs can produce higher amounts of lumens with less energy compared to SMDs and DIPs. COB LEDs uses reflectors to provide a more focused and controlled light.

SMD LEDs are brighter than DIPs when it comes to indoor usage and are also much more energy efficient. They are also used for better flooding of light over larger areas compared to COBs but at the cost of being more glaring.

DIP LEDs are brighter than SMDs when it comes to outdoor usage under direct sunlight.

Longevity and Thermal Performance

COB LEDs have improved thermal resistance and a larger cooling area. Its fewer components and more efficient packaging results in less heat generation, and they transfer heat to heat sinks more effectively compared to SMDs and DIPs. COB LEDs also have the cooling ceramic substrate of the chips which further improves heat dissipation. Hence, lasting longer than its predecessors.

SMD LEDs are introduced with better heat dispersion (low optical decay) and a longer lifespan than DIPs.

Size and Weight

COB LEDs are significantly smaller and lighter than SMDs and DIPs. Therefore, they have more colour uniformity and take less space.

DIP LEDs takes considerably more space and is heavier compared to SMDs and COBs but makes up for it by being more durable and resistant in harsher weather conditions.

Colour Range

DIP and SMD LEDs have many colour options to choose from. With its RGB system, these can be used to create virtually any colour on the spectrum by adjusting the output level.

COB LEDs are only currently available in a limited variety of colours (blue, green, pink, red, pure white, natural white and warm warm white).

Cost

COB LEDs cuts down its costs by a huge margin because of its low maintenance and energy efficiency; which in turn, prolongs its lifespan. This helps to retrench the need for replacements. What’s more, its upfront price is lower as well compared to SMDs and DIPs.

DIP LEDs being the most expensive option overall currently in the market.

LED Technology Continues to Evolve

Other LED chip styles that you may be hearing about in the future include Multiple Chips on Board (MCOB), used in LED bulbs and tubes; Multiple Chips and Cups on Board packages (MCCOB), used for high bay fixtures and floodlights; Stereoscopic Chips on Board (SCOB) and ETP FC (Flip-Chip), a new technology that offers greater heat dissipation, longer life, nearly zero decay and a smaller design for a more focused light beam and greater brightness.

LED technology is constantly evolving and as time goes on, newer production methods and designs will yield ever more impressive LEDs that produce brighter light output and better quality light, all the while using less and less energy.

You can read more on the benefits of LED lights here.

About Us

The average prospective user definitely lacks the technical expertise needed to properly identify and plan an LED solution that is the most suitable for his or her needs. Consequently, the intervention of a consulting firm that is capable of guiding the prospective clients in making the right decision is therefore by all means necessary.

123 LED Lighting is an example of such a company. It basically tests, evaluates and guides consumers in purchasing the right LED equipment. To get started, you can visit our website 123 LED Lighting or Contact Us. A member of its customer care department is always on standby and very eager to receive any incoming inquiries and act on them as soon as possible.